Yes, ammonia is used in refrigeration systems. It serves as an efficient and cost-effective refrigerant.

Ammonia, recognized by its chemical symbol NH3, is a naturally occurring gas that has been utilized in industrial refrigeration applications for over a century. Its popularity stems from its excellent thermodynamic properties and high energy efficiency, which make it a preferred choice for large-scale refrigeration facilities, including those in the food processing, dairy, and brewing industries.

Ammonia’s environmental benefits also contribute to its widespread use; it does not deplete the ozone layer and has zero global warming potential. Despite its advantages, it must be handled with care due to its toxicity and flammability. The industry continues to rely on ammonia due to its proven effectiveness in keeping systems cool under a wide range of operating conditions.

The Role Of Ammonia In Refrigeration

Ammonia plays a crucial role in refrigeration. It cools our food and drinks. This substance is key in many cooling systems. Let’s explore why and how.

Historical Use Of Ammonia As A Refrigerant

Ammonia has been cooling our food for over 150 years. It was first used in the 19th century. People found it very good for making ice. Since then, its use has grown worldwide.

Chemical Properties That Make Ammonia Suitable For Cooling

- Efficient: Ammonia needs less energy to cool. This makes it good for the planet.

- Effective: It can cool things down very fast. This keeps our food fresh.

- Green: Ammonia does not hurt our ozone layer. It is safe for the air.

Because of these properties, ammonia is a top choice for cooling. It is powerful, fast, and friendly to the environment.

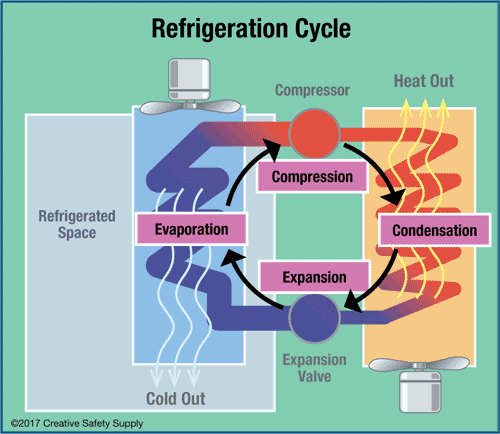

Credit: www.creativesafetysupply.com

Benefits Of Using Ammonia

Benefits of Using Ammonia in refrigeration are well-known in the industry. This natural refrigerant has been in use for over a century. Its unique properties make it highly effective and efficient for large-scale cooling needs.

Energy Efficiency Compared To Other Refrigerants

Ammonia stands out in the refrigeration sector due to its superior energy efficiency. It requires less power to produce the same cooling effect as other refrigerants. This means lower energy bills and reduced operational costs for businesses.

- Higher heat transfer coefficients

- Lower volume per unit of refrigeration

- Requires smaller pipe sizes

Ammonia’s Environmental Impact And Odp

Environmentally, ammonia is a green choice. It has a Global Warming Potential (GWP) of zero. This means it does not contribute to the greenhouse effect. Its Ozone Depletion Potential (ODP) is also non-existent, making it safe for the ozone layer.

| Property | Ammonia | Other Refrigerants |

|---|---|---|

| GWP | 0 | Varies (often higher) |

| ODP | 0 | Varies (some non-zero) |

Ammonia breaks down quickly in the environment. It does not accumulate and pose long-term risks.

Safety Concerns And Regulations

Ammonia plays a critical role in refrigeration. Yet, it poses safety risks. Understanding these risks is vital for anyone involved in the refrigeration industry. Regulations ensure the safe use of ammonia in refrigeration systems. Let’s delve into the specific concerns and the measures in place to mitigate them.

Toxicity And Exposure Risks Of Ammonia

Ammonia, a colorless gas, is highly toxic. It can cause serious health issues upon exposure. The risks associated with ammonia necessitate strict safety measures.

- Inhalation can lead to respiratory distress.

- Skin or eye contact may cause burns.

- High concentrations are potentially fatal.

Exposure limits are set by organizations like OSHA and NIOSH. They ensure worker safety in environments with ammonia.

Safety Protocols And Industry Standards

Industry standards mandate protocols for ammonia refrigeration. These protocols safeguard workers and the public.

| Protocol | Purpose |

|---|---|

| Regular Training | Prepares staff for emergencies |

| Leak Detection Systems | Identifies leaks early |

| Personal Protective Equipment (PPE) | Protects against exposure |

| Maintenance Checks | Prevents system failures |

Compliance with standards like ANSI/IIAR ensures proper safety measures are in place. These measures protect against ammonia-related incidents.

Modern Refrigeration Systems And Ammonia

Ammonia plays a key role in modern refrigeration. This colorless gas is an efficient refrigerant. It cools large spaces at low cost. Ammonia systems are eco-friendly too. They have a long history in industrial cooling.

Advancements In Ammonia-based Cooling Technology

New technology has made ammonia systems better. They are now safer and more energy-efficient. These systems use less ammonia. This reduces potential risks. Advanced sensors and controls help too. They keep the systems running smoothly. This ensures consistent temperatures.

Industrial Applications Of Ammonia Refrigeration

Many industries rely on ammonia refrigeration. Food processing and storage need it the most. Large cold storage warehouses use it. So do dairy and meat processing plants. Ammonia is key in frozen food production too. Chemical and pharmaceutical industries benefit from it.

- Energy efficiency: Ammonia systems use less power.

- Low environmental impact: Ammonia has zero ozone depletion potential.

- Cost-effectiveness: These systems reduce operational costs.

Comparison With Other Refrigerants

Comparison with Other Refrigerants reveals the unique role of ammonia in refrigeration. This comparison explores efficiency, environmental impact, and cost. We assess ammonia against widely used synthetic refrigerants.

Ammonia Vs. Synthetic Refrigerants

- Ammonia (NH3) is a natural refrigerant.

- It boasts high energy efficiency.

- Ammonia has a zero ozone depletion potential (ODP).

- Its global warming potential (GWP) is also minimal.

Contrastingly, synthetic refrigerants like HFCs and CFCs can harm the environment. They have higher ODP and GWP values.

| Refrigerant | ODP | GWP |

|---|---|---|

| Ammonia | 0 | < 1 |

| HFCs/CFCs | > 0 | > 1000 |

Cost-benefit Analysis Of Refrigerant Choices

Choosing the right refrigerant involves cost and benefit review. We consider installation, operation, and maintenance costs.

- Ammonia systems may require higher initial investment.

- They offer lower long-term operational costs.

- Synthetic refrigerants can be cheaper to install.

- They may lead to higher energy bills and maintenance costs.

Ammonia’s efficiency leads to savings, offsetting the upfront cost over time.

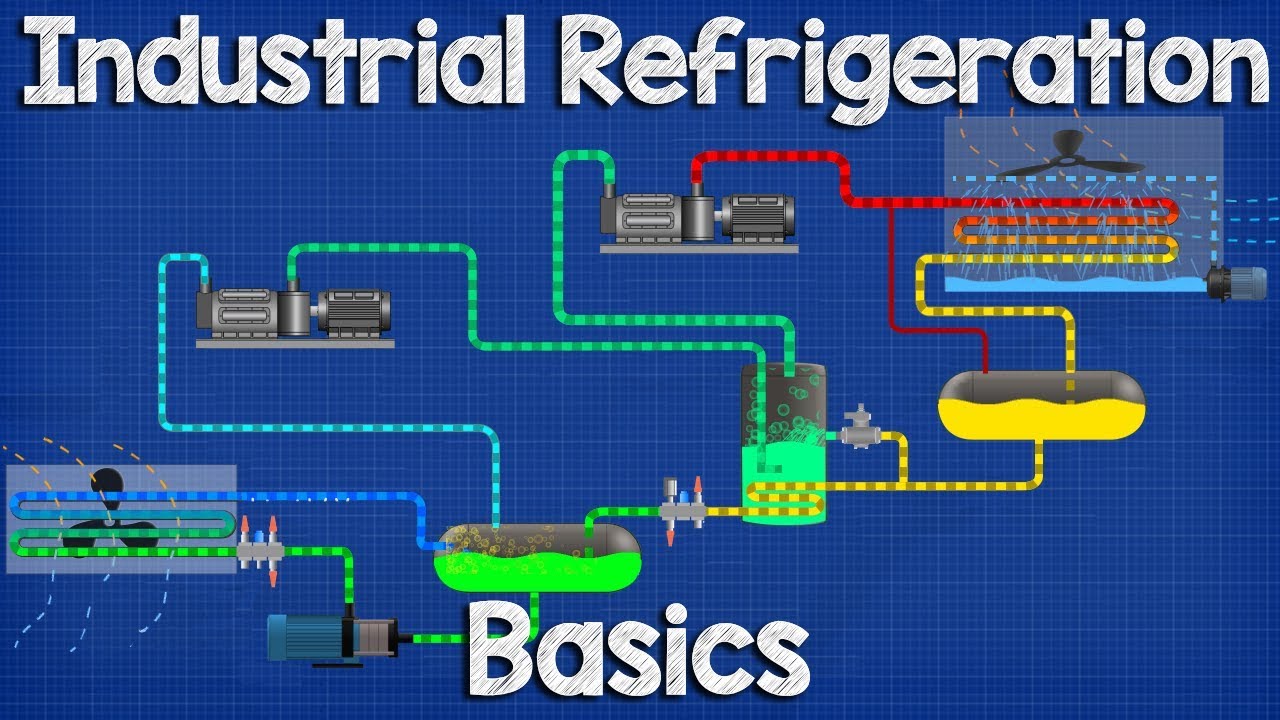

Credit: m.youtube.com

Maintenance And Handling Of Ammonia Systems

Maintenance and Handling of Ammonia Systems are crucial. Ammonia is a common refrigerant. It is used because it’s efficient and eco-friendly. Yet, it can be dangerous if not handled properly. This section covers how to keep ammonia systems running smoothly and safely.

Routine Maintenance Requirements

Keeping ammonia refrigeration systems in top shape requires regular checks. This ensures safety and efficiency. Below are key tasks for routine maintenance:

- Inspect pipes and fittings for leaks or damage.

- Check pressure gauges to ensure proper operation.

- Clean condensers and evaporators to prevent blockages.

- Test safety valves and emergency shutdown systems regularly.

- Review ammonia levels and refill if necessary.

Handling Ammonia Leaks And Emergency Procedures

Ammonia leaks pose serious risks. Quick and proper actions can prevent harm. Follow these steps if a leak occurs:

- Evacuate the area immediately to ensure everyone’s safety.

- Wear protective gear before attempting to deal with the leak.

- Isolate the leak source, if possible, to stop further release.

- Call emergency services for help in managing the situation.

Emergency procedures must be in place. All staff should know these procedures. Drills should happen regularly. This ensures everyone knows what to do during an ammonia leak.

| Action | Reason |

|---|---|

| Evacuate area | Ensures safety |

| Wear protective gear | Prevents harm |

| Isolate leak source | Stops further release |

| Call emergency services | Professional assistance |

Future Of Ammonia In Refrigeration

The Future of Ammonia in Refrigeration looks bright and promising. This natural refrigerant has been a key player for years. Now, it’s set to revolutionize the industry. Let’s explore the innovations and trends that will shape its future.

Innovations In Refrigerant Technology

Recent advances make ammonia even safer and more efficient. Here are some key innovations:

- Compact systems reduce the risk of leaks.

- Hybrid cooling combines ammonia with CO2 for lower temperatures.

- Energy efficiency improvements cut down operation costs.

These innovations help industries save money and protect our planet.

Predicted Trends In Ammonia Usage

Experts believe ammonia usage in refrigeration will grow. Here’s why:

- It’s eco-friendly. Ammonia does not harm the ozone layer.

- It’s cost-effective. Ammonia systems last long and use less energy.

- It’s versatile. From small businesses to large industries, ammonia works for all.

With these benefits, more companies will choose ammonia for cooling.

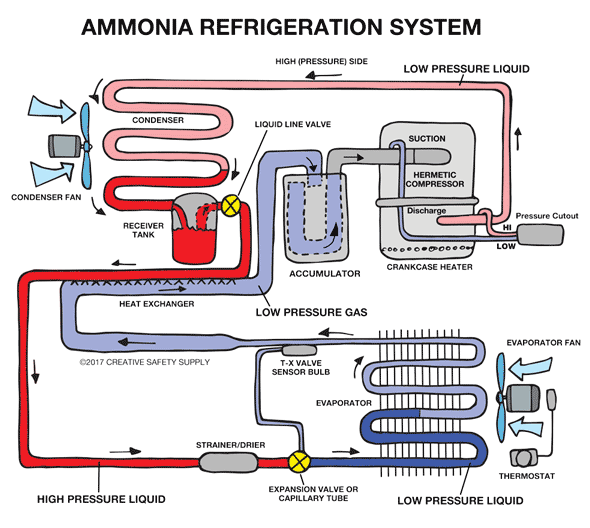

Credit: www.creativesafetysupply.com

Case Studies: Successful Ammonia Refrigeration

Ammonia refrigeration has shaped the cooling industry. Its success stories span from small businesses to global enterprises. Explore real-world cases where ammonia systems excel in efficiency and eco-friendliness.

Real-world Examples Of Ammonia Refrigeration Systems

- Food Processing Plants: Companies like Tyson and Nestlé use ammonia for large-scale cooling.

- Ice Rinks: Ammonia ensures smooth ice surfaces in many arenas.

- Breweries: Craft beer makers rely on ammonia for perfect fermentation temperatures.

Lessons Learned From Ammonia Refrigeration Implementation

- Safety Training: Employees must learn to handle ammonia safely.

- Energy Savings: Ammonia systems can cut energy use significantly.

- Regular Maintenance: Systems need checks to prevent leaks and ensure efficiency.

Frequently Asked Questions

Is Ammonia Still Used In Refrigeration?

Yes, ammonia is still widely used as a refrigerant in industrial refrigeration systems due to its efficiency and eco-friendliness.

When Did Fridges Stop Using Ammonia?

Refrigerators largely stopped using ammonia as a refrigerant in the 1930s, when safer alternatives became available.

Why Ammonia Is Not Used In Refrigerator?

Ammonia is corrosive, posing risks to refrigeration system components and potential safety hazards to users due to its toxicity.

Do Home Refrigerators Use Ammonia?

Most modern home refrigerators do not use ammonia as a refrigerant; instead, they typically use hydrofluorocarbons like HFC-134a or R-600a, which are safer for domestic settings.

Conclusion

Understanding the role of ammonia in refrigeration systems is crucial for industry professionals. This colorless gas plays a key role in cooling processes, offering efficiency and environmental benefits. As we’ve explored, its application demands respect for safety protocols. Embracing modern refrigeration means recognizing ammonia’s significance in achieving sustainable and effective cooling solutions.